|

|

|

|

|

●

|

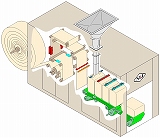

The model EFS-22 roll tube type

automatic bag making and filling

machine includes bag making, product

filling, bag top sealing, and cooling

stations. The machine is designed and

manufactured using state-of-the-art

technology and all functioning

components are integrated into a

compact body.

|

|

|

●

|

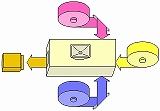

A graphic control panel is used to

adjust sealing temperature timing, and

to change the cutting length. The

versatile graphic panel also provides

an operation monitor, various setting

screens, fault displays, and a

sequencer I/O monitor. All operational

controls are done on the graphic

panel.

|

|

|

●

|

The highly efficien chut realize

high-speed operatio of approximately

30 bags per minute at 25kg per bag.

|

|

|

|

| SPECIFICATIONS |

| Model |

EFS-22 |

| Capacity※1 |

1,850

bags / hr max. |

| Products |

Resin

pellets |

| Set

weight |

20

- 30 kg / bags |

| Film

roll |

Gusseted

roll tube

|

Bag

size

※2 |

Width

of empty bag |

380

to 460 mm |

| Length

of empty bag |

750

to 950 mm

|

| Air

consumption |

1,700NL/min |

| Power

requirements |

24.0

kW |

| Weight |

6.0

t |

|

※1

Varies with the product and oprating environments.

※2

Contact us for applications involving common use

of different bags, use of special bags, and bag

dimensions and setweights outside the above range.

|

|

|

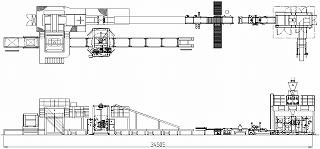

The illustration explain

in detail.

|

The roll stand

may be installed to

match the customer layout (optional). |

|

|

OUTWARD

DIMENSIONS

|

●Dimensions vary with specifications.

EFS-22 bagging system

line for reference

|

Seperate-Type

Roll Stand |

Corner Seal Unit |

Pinhole Unit |

Bottom Seal and

Cutter Unit |

|

|

|

|

Bag Opener and

Filling Unit |

Top Seal Unit |

Top Seal Cooling

Clamp Unit |

Graphic Panel |

|

|

|

|

|

- 規格如有改變不作另行通知

- 每一個型號的圖片及規格都會有所不同

- 未經批准而轉授是禁止的

|

|