|

|

Simplified Model Featuring Direct Charge and Gross

Weighing System |

The model 3CM-5B

bagging machine features a compact body, minimal

footprint and low cost. It also features the

gross weighing system to directly charge and weigh

bags in granular product applications. Bags

are directly held against the chute using a swing

type bag feeder, making operation and maintenance

easy.

|

|

|

Specifications

|

| Capacity※1 |

120

bags / hr max. |

| Set

weight |

20 - 30

kg/bags |

| Bag

type |

Paper

|

| Bag size

※2 |

Width of empty bag |

380 -

460 mm |

|

Length of empty bag

|

750 to

950 mm |

| Air

consumption |

300

NL/min |

| Power requirements |

1.5 kW |

| Weight |

0.7 t |

※1Varies with

the product and operating environments.

※2Contact us for

applications involving common use of different

bags, use of special bags, and bag dimensions

and set weights outside the above range.

|

|

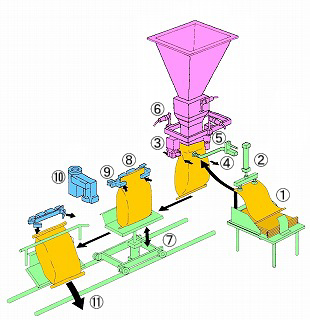

Names of Units

1. Feeder

Place bags neatly with top opening facing

front. The magazine holds approximately 50

bags.

2. Pickup Unit

Bags are picked up one at a time, turned 90

degrees, and set on the filling station.

3. Clamping Unit

Each bag is clamped at both edges with 30mm wide

clamps. Clamping is checked to insure

accuracy.

4. Bag Opening Unit

Suckers pull open the bag mouth and then release

using a vacuum generator. Timing is

adjusted with the pickup and takeout. The

clamps shift inward when the bag mouth is opened

by vacuum.

5. Filling Station

The specially designed expansion spout

(conventional hopper that is turned 90 degrees)

fills the product. The clamps stretch out

to spread the gussets after filling.

6. Weighing Machine

The clamp and filling station is suspended on

three load cells. Auto zero adjust is

performed automatically with the empty bags.

7. Carrier Table and Bottom Tapper

The carrier table moves to the hopper position

as filling starts. The bottom tapping

plate supports the bag from below and taps the

bag to facilitate settling.

8. Bag Former

After the gussets are fully unfolded, the bag

mouth is neatly formed and held between press

bars on the hopper and the carrier table.

9. Bag Gripper

The carrier table transports the bag to the

sewing head while the bag is firmly gripped from

both sides.

10. Sewing Machine (DS-6AC)

The sewing head starts operation upon detecting

an approaching bag. The grippers release

the bag. The sewing head stops upon

detecting the trailing edge of the bag.

11. Discharge

The carrier table stops in a preset

position. The bottom tapper inclines and

the bag slides off the machine. |

|

|

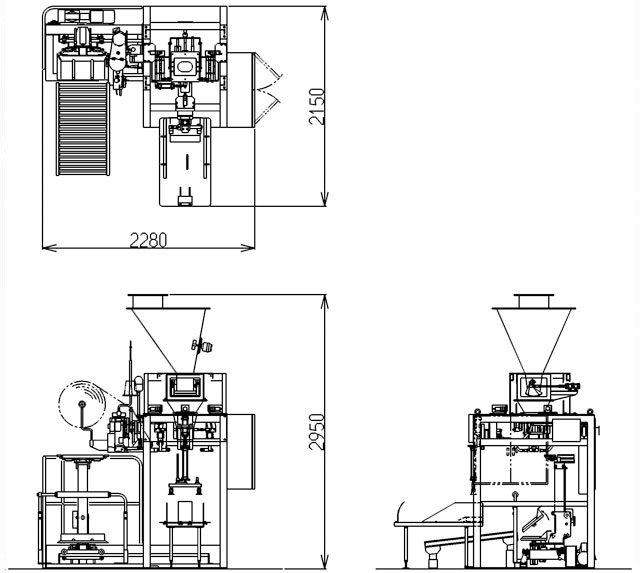

OUTWARD

DIMENSIONS

|

|

Dimensions vary with specifications. |

- Specifications should be changed

without previous notice

- There are some differences between

shown picture and specifications of each MODEL.

- Diversion without permission should

be prohibited.

|

|