|

|

|

|

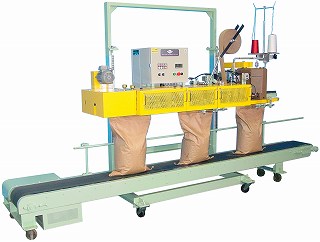

FILLED BAG CLOSING MACHINE

WITH HEAT SEAL TAPE- SEALER

FRONT SEWING MACHINE TYPE

|

|

|

Photograph

is model KS-14 Photograph

is model KS-14 |

With

options (BC4000 Conveyor) With

options (BC4000 Conveyor) |

|

|

Standard

Specification

|

|

Specs

|

Sealing speed

|

Heater (W)

|

Drive (kW)

|

Power (kW)

|

|

Range

|

Capacity

|

Sealer

|

Sewer

|

|

KS-12

|

6 ~ 10m/min

|

500 x 4

|

0.4

|

0.4

|

3

|

|

KS-12C

|

|

KS-13

|

500 x 6

|

0.4

|

4

|

|

KS-13C

|

|

KS-13D

|

|

KS-13DC

|

|

KS-14

|

500 x 8

|

0.4

|

5

|

|

KS-14C

|

|

KS-14D

|

|

KS-14DC

|

|

KS-16

|

500 x 12

|

0.75

|

7.5

|

|

KS-16C

|

|

KS-16D

|

|

KS-16DC

|

|

|

Standard

Specification

|

|

Specs

|

Dimensions (mm)

|

Weight

(kg)

|

Options

|

Applications

|

|

Length

|

Width

|

Dust cleaner

|

Crepe tape

|

|

KS-12

|

2,100

|

1,290

|

ca.350

|

-

|

-

|

Over-tape

Innermost ply

PE film seal.

|

|

KS-12C

|

2,450

|

1,290

|

ca.400

|

-

|

○

|

|

KS-13

|

2,300

|

1,290

|

ca.380

|

-

|

-

|

For flat 3

paper plies.

Over-tape

inner ply seal

|

|

KS-13C

|

2,650

|

1,290

|

ca.450

|

-

|

○

|

|

KS-13D

|

2,580

|

1,290

|

ca.420

|

○

|

-

|

|

KS-13DC

|

2x960

|

1,290

|

ca.500

|

○

|

○

|

|

KS-14

|

2,500

|

1,290

|

ca.420

|

-

|

-

|

For flat 4

paper plies.

Over-tape

inner ply seal

|

|

KS-14C

|

2,860

|

1,290

|

ca.500

|

-

|

○

|

|

KS-14D

|

2,780

|

1,290

|

ca.460

|

○

|

-

|

|

KS-14DC

|

3,160

|

1,290

|

ca.550

|

○

|

○

|

|

KS-16

|

2,960

|

1,290

|

ca.500

|

-

|

-

|

For flat 6

paper plies &

gusseted 3

paper plies.

Over-tape

inner ply seal

|

|

KS-16C

|

3,310

|

1,290

|

ca.600

|

-

|

○

|

|

KS-16D

|

3,240

|

1,290

|

ca.550

|

○

|

-

|

|

KS-16DC

|

3,620

|

1,290

|

ca.650

|

○

|

○

|

|

- Temp. adjust range 0 to 400℃

- Air req. 200NL/min(at 0.5MPa)

Pressure 0.5Mpa(5kg/c㎡) (varies with speed)

- Sealer height adjust range

800~1400mm

- Add 0.55KW(50Hz) or 0.72KW(60Hz)

power when optional dust cleaner is installed.

- Above speeds are not guaranteed

ones. They are given for reference only.

- Length of the machine (L) varies

slightly between manual insertion type and packaging

machine coupling type.

- KS ー 1□ D

- Kraft sealer ― 1:Rear sewer □:Heater

pairs D:Dust cleaner S:Crepe tape

|

|

OUTWARD

DIMENSIONS

|

|

|

Dimensions vary with specifications. |

|

|

|

Printer

|

Heater

|

Dust cleaner

|

Over-tape unit

|

|

|

Seal-bag Top

Closing Sewing Machine DS-11,DS-7A/C

|

|

|

|

|

|

|

|

Patent applied

|

Thread cutter :

A-Automatic thread cutter

C-Automatic crepe tape cutter

|

|

- Virtually sealed up OMPB top closing

with heatsealable over-tape or innermost ply PE film

seal.

- Crepe-tape bound closure.

- No failure and easy maintenance

because of fewer parts than conventional sewers.

- Upper and lower bag feeder

synchronizes with the automatic bag feeder mechanism.

- Specifications should be changed

without previous notice

- There are some differences between

shown picture and specifications of each MODEL.

- Diversion without permission should

be prohibited.

|

|