|

|

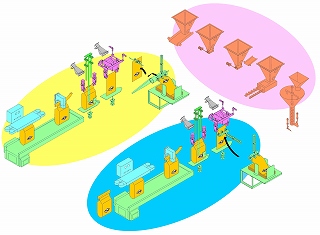

Gross Weighing Series |

|

1. Gross weighing

system featuring low equipment height, reduced

footprint, compact design, and economical cost.

2. The product supply system can be chosen according to

the properties of the product.

3. Applicable for a wide range of products, from

free-flowing materials to fine powder.

4. Chance of low bagged product weight due to adhesion

or air dispersion is reduced since the product is

discharged directly into the bag.

|

|

|

Specifications

|

| Capacity※1 |

300/250

bags/hr max. |

| Set

weight |

20 - 30

kg/bags |

| Bag

type |

Paper

Cloth bags

PE bags |

| Bag size

※2 |

Width of empty bag |

380 -

460 mm |

|

Length of empty bag

|

750 to

950 mm |

| Air

consumption |

500

NL/min |

| Power requirements |

4.3/3.2

kW |

| Weight |

2.5/2.0

t |

※1Varies with

the product and operating environments.

※2Contact us for

applications involving common use of different

bags, use of special bags, and bag dimensions

and set weights outside the above range.

|

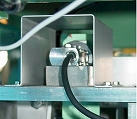

Load cell (3 places)

Weigh mechanism

Gross weighing uses a 3-point load cell hanging

system. Functions include automatic correction

of drop height, automatic zero adjust (tare

erase), estimated discharge, discharge

correction, memory and integration, and digital

display. |

|

|

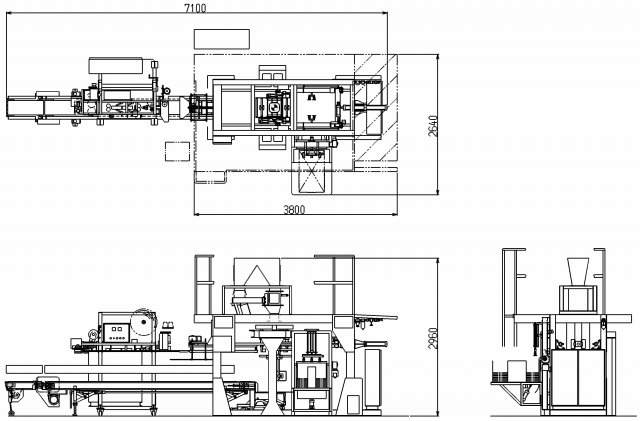

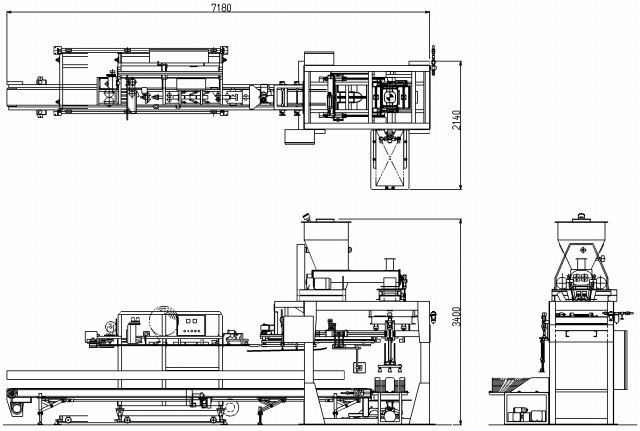

OUTWARD

DIMENSIONS

|

3CM - 3G

*The

product supply unit comprises an electromagnetic feeder

and a cut gate.

3CM - 5G

*The product supply

unit is the screw feeder type. |

Dimensions vary with

specifications. |

- Specifications should be changed

without previous notice

- There are some differences between

shown picture and specifications of each MODEL.

- Diversion without permission should

be prohibited.

|

|