|

|

|

|

|

Bottomer

|

|

5B

|

|

5B-SP

|

|

6B-2

|

|

6B-3

|

|

6B-4

|

|

8B

|

|

213B-PV

|

|

216B

|

|

216B-PV

|

|

220B

|

|

220B-PV

|

|

222B

|

|

222B-PV

|

|

712B

|

|

713B

|

|

612B

|

|

613B

|

|

913B-PV

|

|

913B2-PV

|

|

|

|

BM5216

|

|

BM5116

|

|

BE613-PV

|

|

|

|

|

|

|

|

|

|

For producing general pasted bags.

Reduced time for size change and adjustment and improved

operability.

|

|

|

Photograph is model BM5216 |

|

Machine

Specifications

|

|

Model

|

BM5216

|

|

Speed

|

Max.200 bags/min

|

|

Bag Length

|

340 - 940mm

|

|

Tube Length

|

|

|

Bag Width

|

300 - 600mm

|

|

Bottom Width

|

70 - 160mm

|

|

Width of Opened-out Bottom

|

180 - 380mm

|

|

Distance between Bottom

Center

|

270 - 780mm

|

|

Valve Patch

|

|

Cut-off Length

|

80 - 220mm

|

|

Paper Roll Width

|

100 - 350mm

|

|

Valve Patch Roll Diameter

|

Max.1,100mm

|

|

FEATURES

|

|

The frame traverser,

bottom width creaser and bottom former are

numerically controlled (option).

|

|

The auto-inspection system

detects double-fed or mis-aligned tubes,

front/back of a tube, correct grip of valve

sheet, inner bottom patch and bottom patch,

presence of a valve sheet, and correct bottom

formation.

|

|

The bottom, after opened,

proceeds to the bottom forming unit while it

is held vertically so that the operator can

make necessary adjustments easily directly

facing the opened bottom.

|

|

|

|

|

Standard Equipment

|

|

1 Rotary

Feeder

|

10 Bottom

Forming Unit

|

|

2 Tube

Alignment Unit

|

11 Bottom

Patch inserting Unit

|

|

3 Diagonal

Creaser

|

12 Flexo

Printers For Bottom Patch

|

|

4 Center

Creaser

|

13 Bottom

Patch Reel Stand

|

|

5 Bottom

Opening Unit

|

14 Bottom

Turning Unit

|

|

6 1st. Valve

Unit

|

15 Bag

Ejector

|

|

7 1st. Valve

Reel Stand

|

16 Pressing

Unit

|

|

8 2nd.

Creaser

|

17 Stacking

Unit

|

|

9 Bottom

Pasting Unit

|

|

|

|

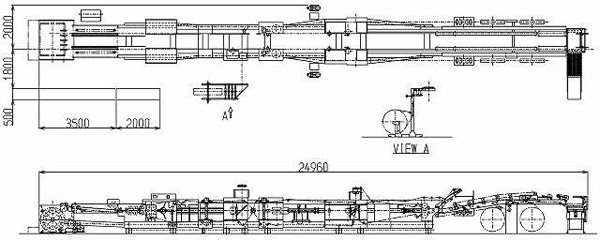

OUTWARD

DIMENSIONS

|

|

Dimensions vary with specifications. |

- Specifications should be changed

without previous notice

- There are some differences between

shown picture and specifications of each MODEL.

- Diversion without permission should

be prohibited.

|

|